A one-stop-shop for Innovative printing solutions

Enjoy the Difference

Our mission is to provide our diverse client base with a one stop service aimed at delivering products that consistently meet the customers needs and expectations in terms of speed to market, quantity, quality and price.

We get things done

From packaging to books, we go the whole nine yards for our customers

Our Process

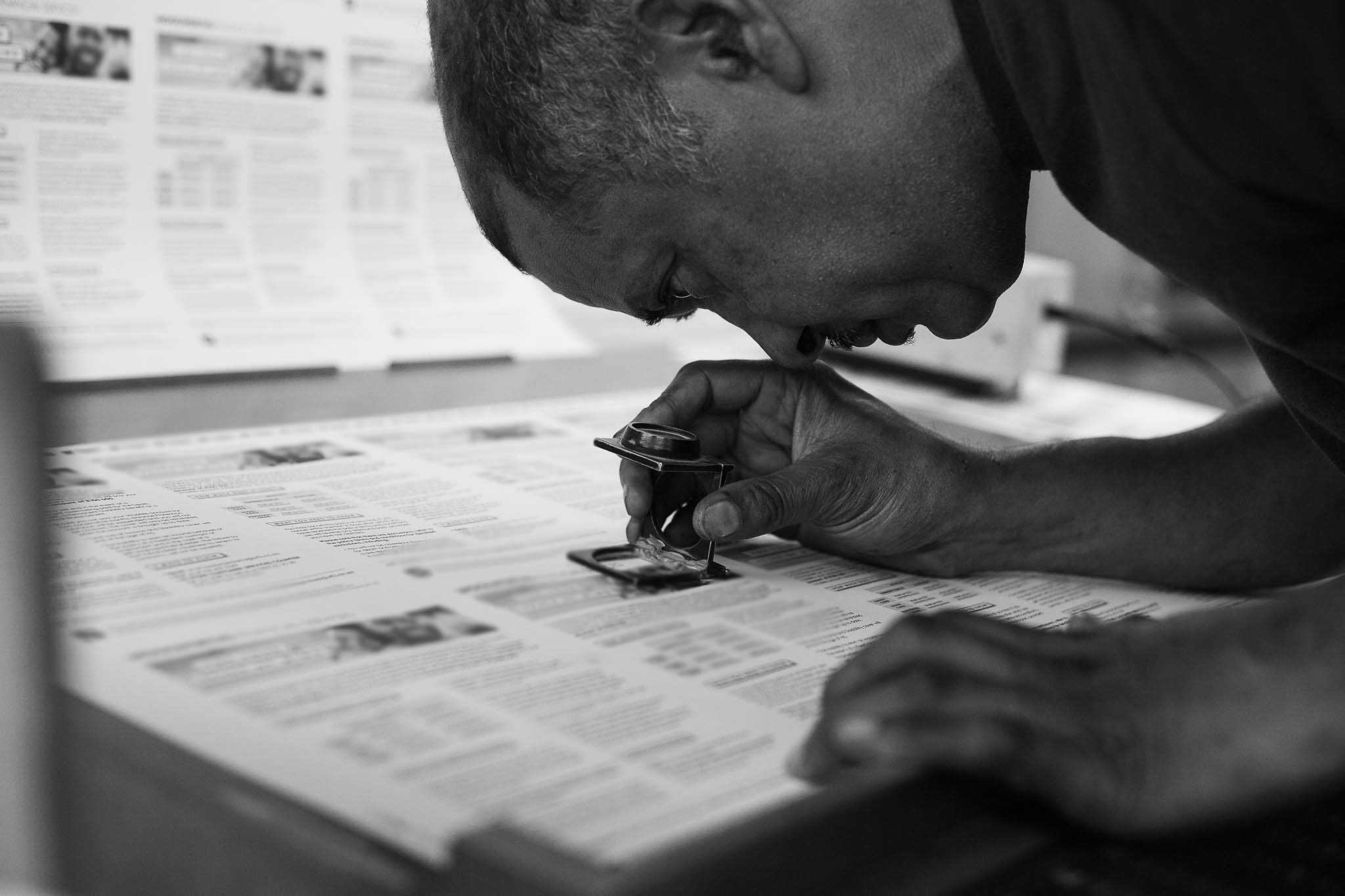

Step 1: Origination

All of the different stages used to create and prepare a job before it is ready to print. Our long serving dedicated staff regularly perform quality control assessment to ensure that DNP maintains a consistently high standard of colour printing on all your printing presses and proofing devices.

Step 2: Digital-to-Print

Desktop publishing software are used to create and design an electronic document, by using page layouts, producing typographic quality text and images etc. When necessary calibration adjustments are made to our on-site Epson proofer device to cater for any footprint variance on our presses.

Step 3: Print

Once the Epson proof has been signed off by the client and the plates have been made, the job will be printed on one of the selected lithographic machines. There is the option of an overprint varnish that has a satin finish and prevents scuffing.

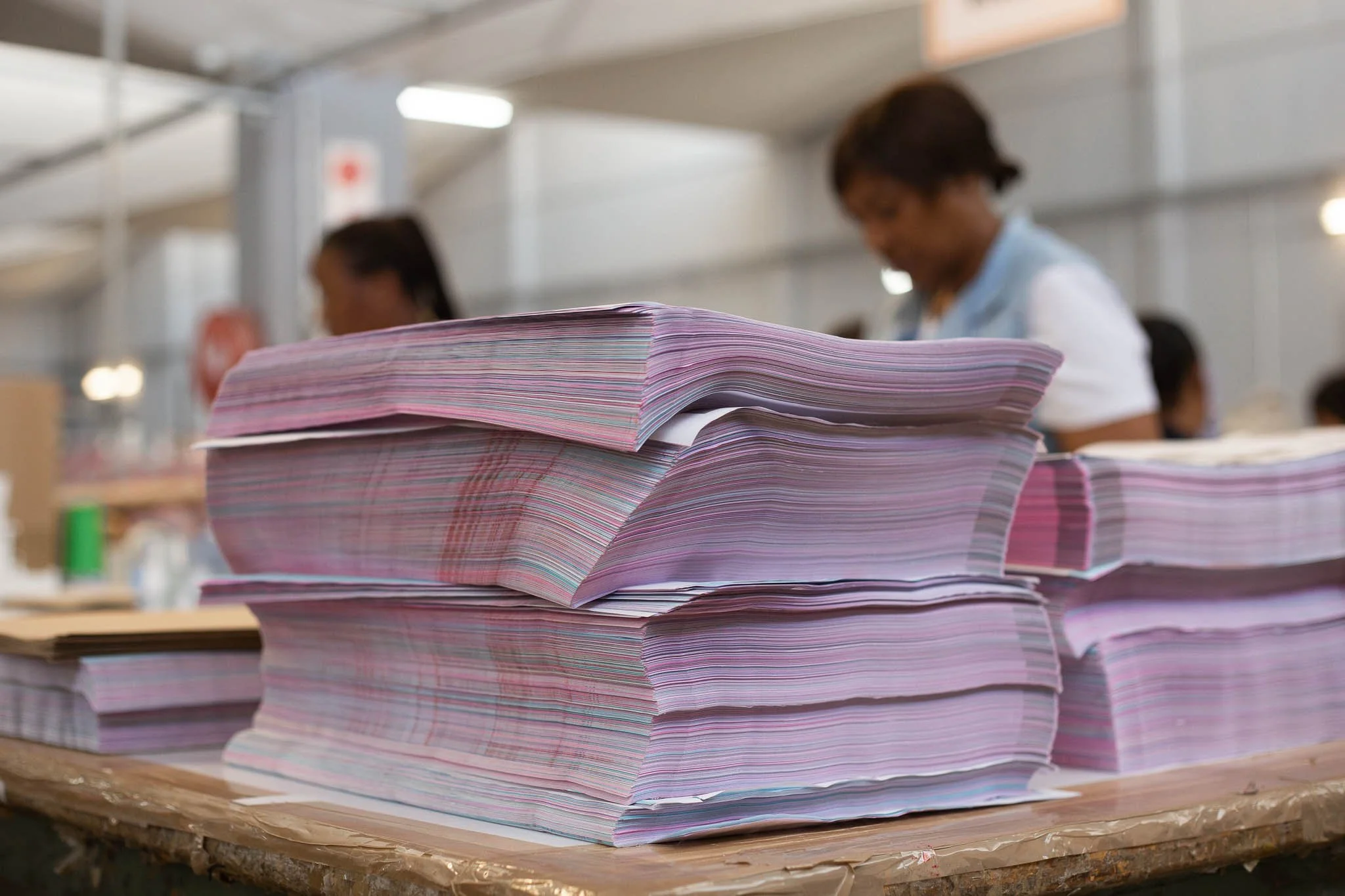

Step 4: Finish

Once the print process is completed, the printed sheets will go to the next department where the finishing takes place, this is either straight forward guillotine work, or it can be die-cut, perforated and folded. Or sections inserted and stitched in a gang stitcher. Once this is complete the job is sent through to Despatch.

Step 5: Despatch

We are able to pack on requisition. Alternatively we will palletise and hand over to delivery.

Step 6: Delivery

We are able to despatch to one address in Cape Town using our vehicles, or alternatively we can distribute nationally. Once despatched from our warehouse you can contact us to receive live tracking updates.

Knowledge, Experience & attention to detail

Behind the Scenes

A glimpse of what happens behind the scenes whilst you wait for your print order. See how efficiently our team operates with high volume orders in limited time to meet our client deadlines.